Product Applications

Using CIRA Water Purifiers for Ion Chromatography

Trovion has partnered with Dionex Corporation, the world leader in ion chromatography, to bring to the IC market new ion analysis capabilities. For more information, please see the links on our Literature page.

IonPrep/AutoPrep - The Ultimate Solution for Ultra-trace IC Analysis

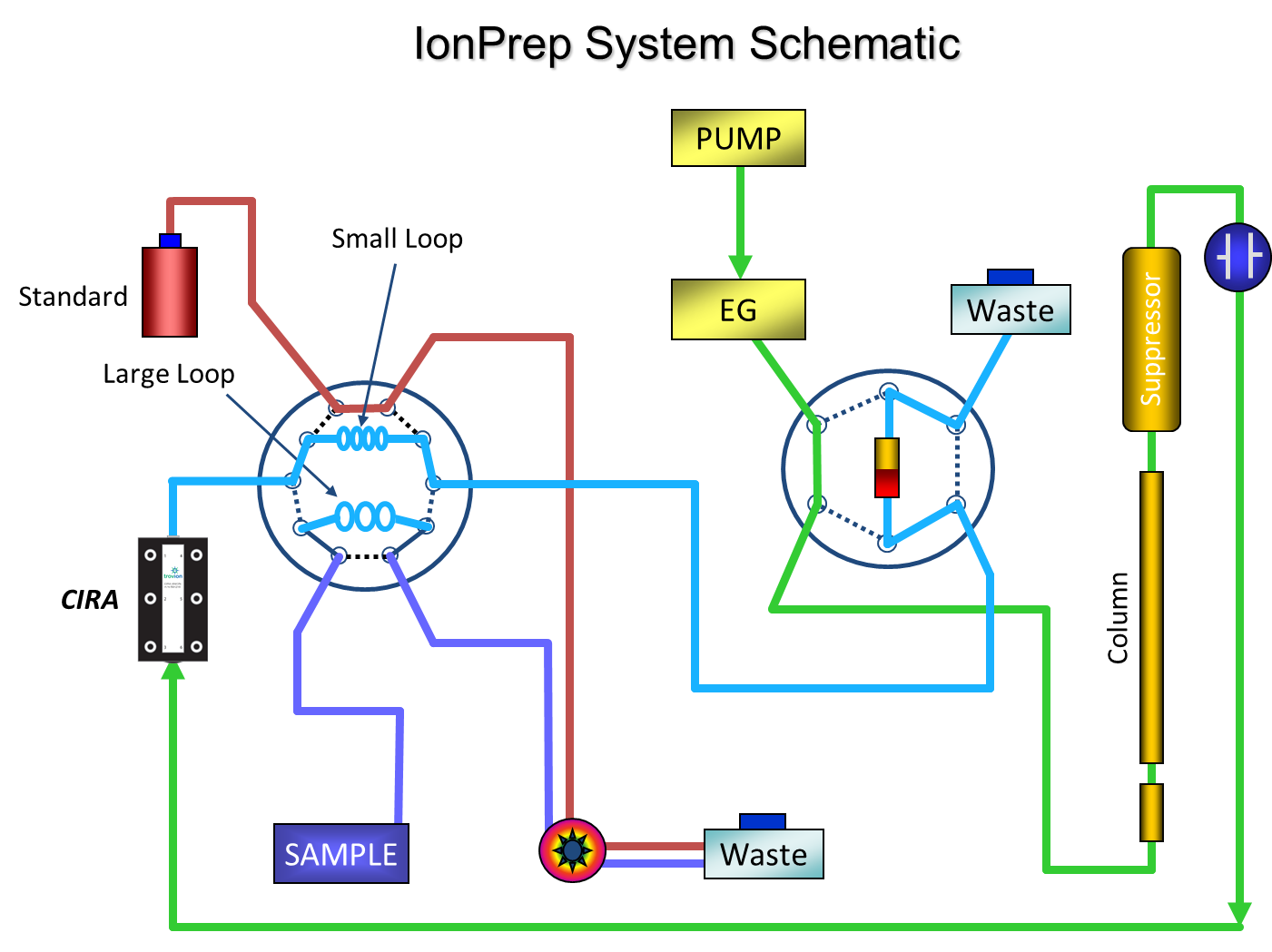

Conventional trace analysis in ion chromatography requires in-line concentration of the sample. An external sample pump is used to deliver the water sample (5-100 mL) through a concentrator column where the analytes are quantitatively retained. Sample carry-over and contamination from the sample pump compromises calibration and sample loading. This results in a higher chemical blank, poor reproducibility and higher detection limits. Preparation of sub part-per-billion calibration standards are equally problematic. The problems of trace analysis have been solved using IonPrep. IonPrep uses a CIRA water purifier, which solves the chemical blank problem and results in greatly improved detection limits and a more reliable system.

How it Works:

IonPrep consists of four major processes:

1. Water Purification

2. On-line Standard Preparation

3. Sample-standard transfer

4. Analysis.

1. Water Purification

In conventional IC analysis, the conductivity cell waste is directed to waste (either directly or through the suppressor). In IonPrep, the conductivity cell waste stream is directed to the CIRA water purifier, where the water stream is completely deionzed producing ultrapure water. This ultrapure water is used in-line for standard preparation, transfer of standard and sample to a concentrator column and for rinsing all tubing and components to eliminate carry-over.

2. On-line Standard Preparation

IonPrep uses a 10 port valve on the low pressure side (prior to the standard injection valve) with a small loop (typically 10 uL) and a sample/dilution loop (typically 10 mL). The small loop is used for loading the standard. A single standard is used which is typically prepared at the low ppb level (5-30 ppb). Using a single standard at the ppb level results in a more chemically stable standard which has a low chemical blank.

The waste flow from the conductivity cell is passed through the CIRA electrolytic purifier which then passes to the 10 port valve which is typically containing a 10 µL loo. The 10 µL loop is used to deliver standard for system calibration. The 10 uL loop is loaded multiple times to create a multi-level calibration curve. A 10 mL loop is used for the sample. The two loops are calibrated so the exact volume ratio is known and used for quantitiation. In this example, the volume ratio of the standard and sample loop is 1000-fold, thus, injection of 10 µL of a 10 ppb standard corresponds to calibration at the 10 ppt level. A blank run is accomplished by filling the large loop (10 mL) with the ultrapure water and injecting it (same as a sample).

3. Sample-standard transfer

The CIRA ultrapure product water is used to transfer the standard and sample to the concentrator column of the six port valve. The precise flow of the ultrapure water (originating form the analytical pump) and the low ionic contamination of the water ensures a low and very reproducible chemical blank. Low and reproducible blanks are key elements of IonPrep.

4. Analysis

The final step of IonPrep is the IC analysis. The IC analysis uses Dionex RFIC eluent generation (RFIC EG) technology with electrolytic suppression (SRS) for optimum separation and detection capability. As the suppressed eluent exits the conductivity cell, the suppressed eluent waste is directed to the CIRA, where it is deionzed and the ultrapure water product is used for the IonPrep standard preparation, standard and sample loading and rinsing.

Feautres of IonPrep include:

- A single pump and fluid stream used for chromatography and sample loading

- No contamination of sample

- Minimal carry over from standards and samples

- Easy to prepare, single standard used for automated multi-level calibration

- Ultrapure water produced in-line (from CIRA) for standard preparation, rinsing, and sample loading

- Extremely low blanks due to ultrapure water used for standard and sample processing

- Detection limits at the low to sub part-per trillion level

IonPrep with In-Line Sample Pretreatment

The IonPrep technique can also be used with in-line sample pretreatment chemistries. In these applications, a cartridge containing the chemistry for matrix or selective analyte removal is placed between the sample valve (ten port) and the injection valve (six port) with concentrator column. Chemistries for in-line sample pretreatment include chloride removal (silver form cation exchange resin), sulfate removal (barium form cation exchanger), protein, organics removal (polymeric reversed phase) and humic/fulvic acids (polyvinylpyrrolidone). For more information on in-line sample pretreatment, click here (link to .pdf file).